What Are the Benefits of Low Smoke Zero Halogen Cables?

When you choose cabling for IT, communications or networking systems, your main aim is to buy the right cables for the job. However, you should also look at other factors before you choose which products to install.

For example, the jackets that go around the outside of cables can also affect your build. While regular plastic jackets do a good job, you might see extra benefits from buying low smoke zero halogen (LSZH) products.

Why are LSZH cables different? What are the advantages of using them?

What are LSZH cables?

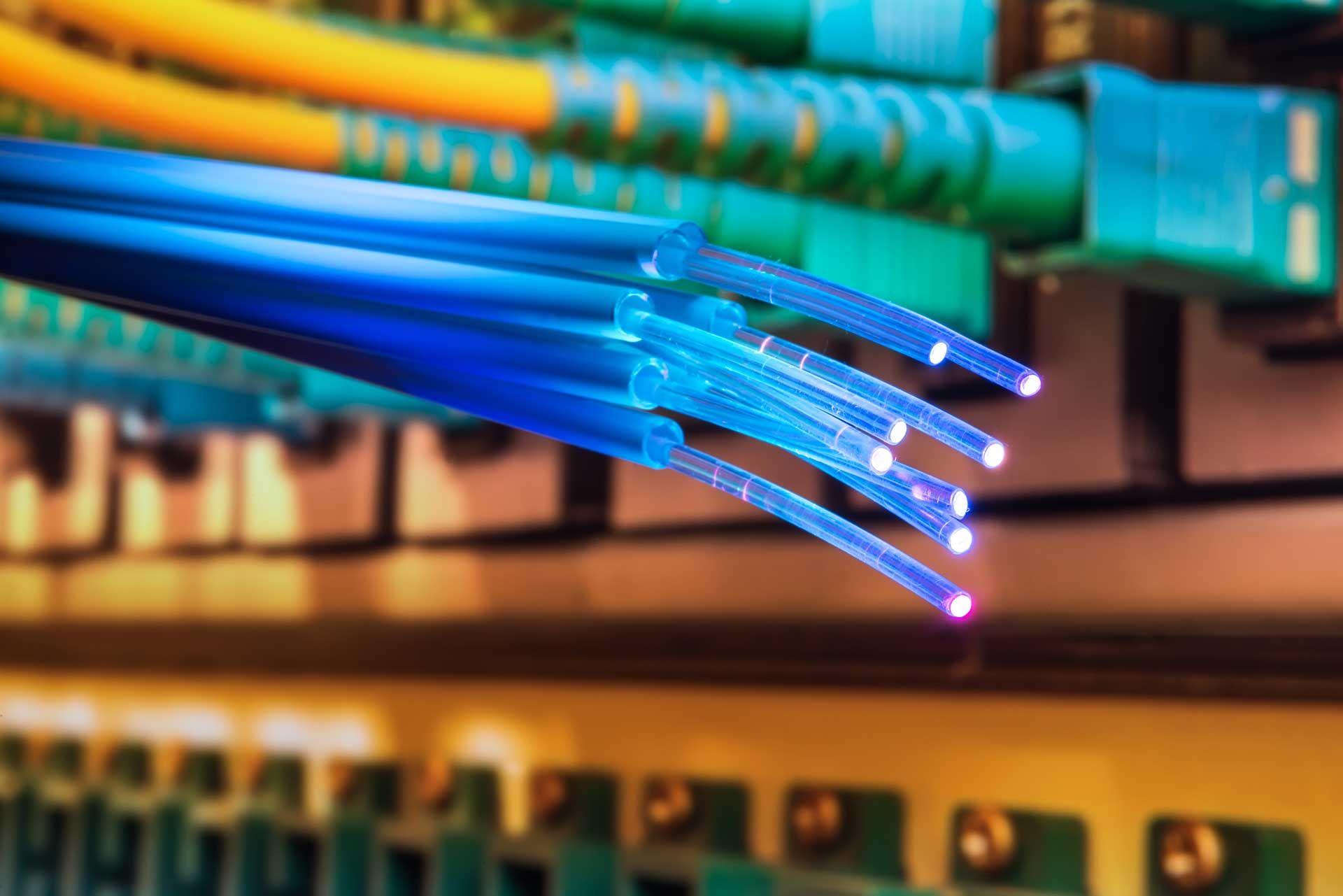

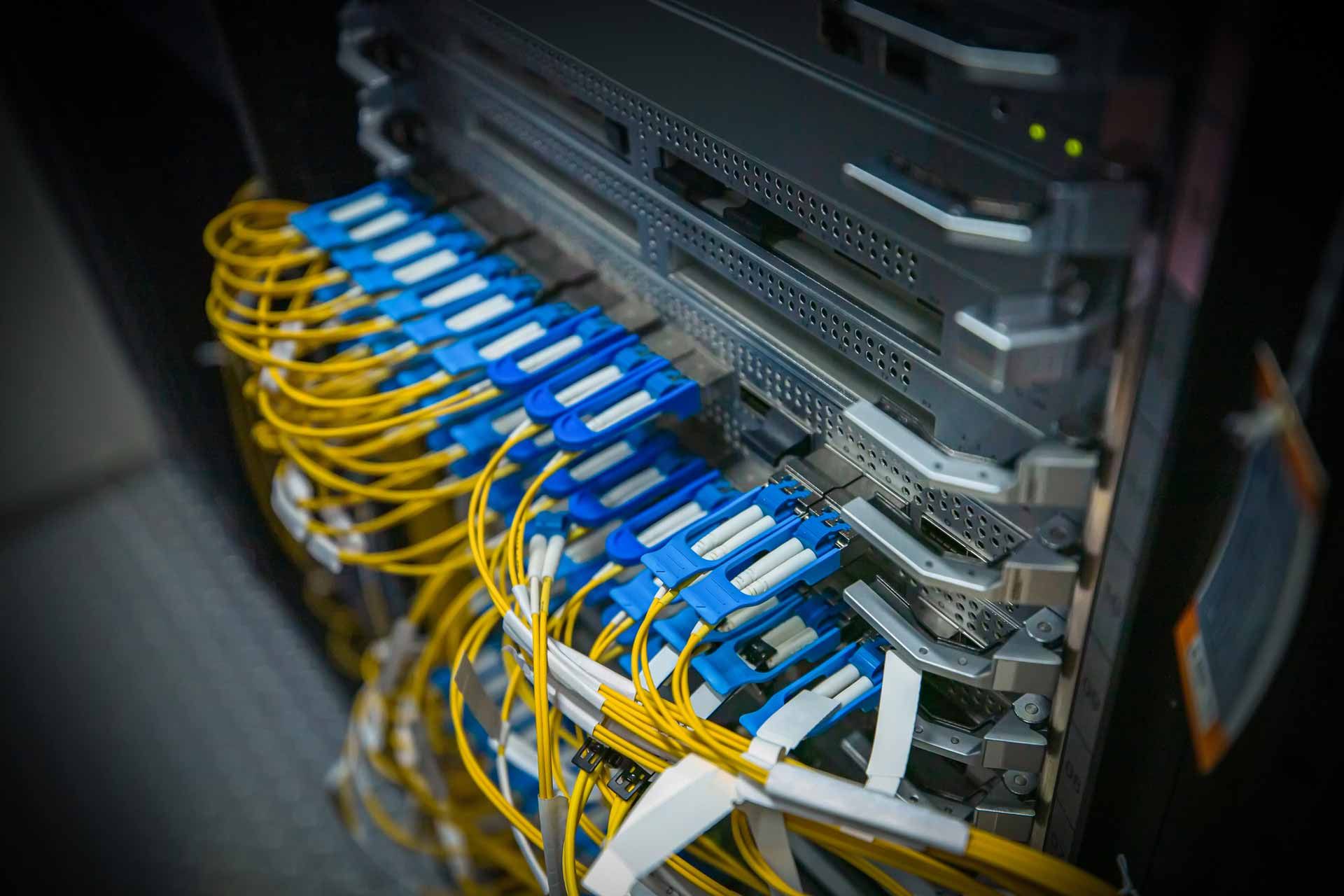

Cables have external covers known as jackets. These jackets protect the inner cables from mechanical, accidental and environmental damage.

Regular jackets are often made from standard plastics like PVC. However, some jackets are made from more advanced plastics such as LSZH.

LSZH jackets are made from thermoplastics or thermoset compounds. While they protect cables like any other jackets, their composition is different.

For example, regular jacket materials often create or contain halogens, such as fluorine, chlorine and bromine, to boost their ability to cope with fire. However, an LSZH jacket should be completely free from any halogens.

This lack of halogens means that an LSZH jacket reacts differently in certain situations. These reactions give this kind of cable some advantages that you won't get from other products.

What are the benefits of using LSZH cables?

LSZH cables have some additional safety and longevity benefits that you might find useful. What can these materials do?

Reduce the spread of fire

Some cable jacket materials can't cope with exposure to fire. They don't have any or enough flame retardance to stop a fire from spreading. Some might actually burn much too easily.

If a plastic jacket catches fire and then starts to burn, then the cable could spread flames on to other cables and components close to it. The fire could spread to your IT equipment. Plus, if the cable runs between rooms or floors in your building, then the cable could help the fire spread. You might find it harder to contain the fire and to minimise the damage it causes.

If your cables have LSZH jackets, then they are better able to cope with a fire. The jacket should have more fire resistance.

Plus, if you buy a high-quality product, then the material might also have self-extinguishing properties. Even if a cable were to catch fire, it shouldn't help the fire spread and its own flames should die out once the source of the fire is extinguished.

Keep people safer

If you have a fire that affects your cables, then any people in the immediate area might be adversely affected. They might not be able to get out of harm's way easily and quickly, especially if a cable burns in a room without much ventilation.

Cables that contain or create halogens when they burn will produce a lot of dark, dense and harmful smoke. They can also let off dangerous gases and fumes. Smoke and toxic substances can prevent people from exiting the area. They might not be able to see a path out; they might be in some physical discomfort.

LSZH cables don't create environmental dangers if they do catch fire. They will emit some smoke; however, it will be less dense and dark. People should be able to see through it. Plus, these cables don't contain or create halogens. So they won't produce toxic gases or fumes. Any people in the area can focus on dealing with the fire or leaving the building.

Give longer-lasting protection

Conventional jacketing plastics are often very flexible. However, LSZH cables tend to be more rigid. Their compounds typically contain additives which affect their ability to flex.

A more rigid cable isn't necessarily a disadvantage. A stiffer jacket can give more protection to its cable; it might not get damaged as easily as a softer and more flexible product.

To find out more about the benefits of LSZH cables and whether they are the best fit for your system, contact Cable Source Pty Ltd.